Why choose PHC piles for solar trackers?

By Himan Shu | July 24, 2025

The main reasons for choosing PHC (Prestressed High-Strength Concrete Pipe Piles) precast piles for installing solar tracking system are based on their advantages in terms of load-bearing capacity, construction efficiency, economy, durability, and adaptability to complex geological conditions.

In solar tracking systems, PHC have become the preferred foundation solution for ground-mounted PV plants due to their standardized industrial production and excellent mechanical performance. These piles are manufactured using centrifugal forming technology, with concrete strength grades typically ranging from C80 to C100. Internally, they are reinforced with prestressed steel bars with tensile strength no less than 1420 MPa, enabling each pile to achieve a vertical bearing capacity of 800 to 3000 kN.

Whether dealing with dynamic loads or challenging terrain conditions, PHC piles offer high adaptability. Their structural reliability and ease of deployment make them particularly well-suited for PV projects requiring fast-track construction.

Application Scenarios

PHC are widely applied in solar projects, meeting the demands of diverse terrains and environmental conditions. On sloped terrains with gradients ranging from 5° to 25°, adjusting the pile length (typically 8 to 25 meters) and inclination, combined with pile diameters between 400 mm and 600 mm, can significantly reduce earthwork volume while maintaining the structural stability of the PV support system.

In soft soil foundations such as silt or backfill layers, PHC piles can penetrate weak strata to reach the bearing layer. The design bearing capacity per pile is generally set between 1200 and 2800 kN, ensuring long-term structural integrity and preventing settlement of the PV system.

In regions prone to high wind loads, PHC piles exhibit excellent bending resistance, with ultimate bending moments reaching 180 to 675 kN·m. This effectively mitigates horizontal thrust and wind-induced vibrations resulting from frequent rotation of the solar tracking structures.

Key Construction Process

During pile installation, hydraulic static pressing or impact driving is commonly employed. For static pressing, hydraulic jacks can apply forces ranging from 800 to 3000 kN, minimizing environmental disturbance in sensitive areas. Impact driving utilizes diesel hammers with impact energy between 35 and 120 kJ, allowing for efficient pile driving with an average installation time of 20 to 40 minutes per pile.

For pile splicing, weld seams must have a minimum thickness of 14 mm, and the welded area should be coated with epoxy bitumen to ensure corrosion resistance in saline or moist environments. At the pile head stage, pre-embedded flange plates must be leveled with a horizontal deviation of no more than 1°.

Secondary grouting is performed using C40 micro-expansive concrete to fill the inner cavity of the pile. At this stage, the lightning protection and grounding system is also integrated, forming a complete and durable foundation system.

Throughout the construction process, critical parameters such as vertical deviation (<1%), final penetration depth (≤20 mm per 10 blows), and pile top elevation tolerance (±30 mm) must be continuously monitored to ensure pile quality and structural reliability.

Technical Advantages

PHC precast piles offer dual benefits of efficiency and reliability in solar PV applications. Compared to traditional cast-in-place piles, their industrialized production process reduces concrete consumption by up to 40% and labor requirements by around 60%, while shortening the construction cycle per pile by over 50%—perfectly aligning with the fast-paced nature of PV project deployment.

Constructed from high-strength concrete and prestressed steel bars, the piles achieve compressive strengths exceeding 80 MPa. Combined with a three-layer anti-corrosion system—including dense concrete structure, surface coating protection, and cathodic protection—they are engineered to maintain a service life of over 50 years even in saline environments with chloride ion concentrations ≤ 5000 mg/L.

Highly Adaptable

PHC piles are suitable for various geological conditions, including cohesive soil layers, sand layers, and strongly weathered rock layers.

In photovoltaic projects around the world, PHC piles are widely used in various geological conditions and demonstrate good adaptability and stability.

In addition, PHC piles have relatively low horizontal bearing capacity, but under reasonable design and construction conditions, they can still effectively support the horizontal loads of solar tracking brackets.

Short Construction Period

PHC piles are prefabricated in factories and installed using the static pressure method during construction, which is fast, vibration-free, noise-free, and has little impact on the surrounding environment.

Compared with traditional cast-in-place piles or drilled piles, PHC piles are more efficient to install, significantly shortening construction time and reducing construction costs. This advantage is particularly prominent for solar projects that require rapid deployment.

Corrosion Resistance And Durability

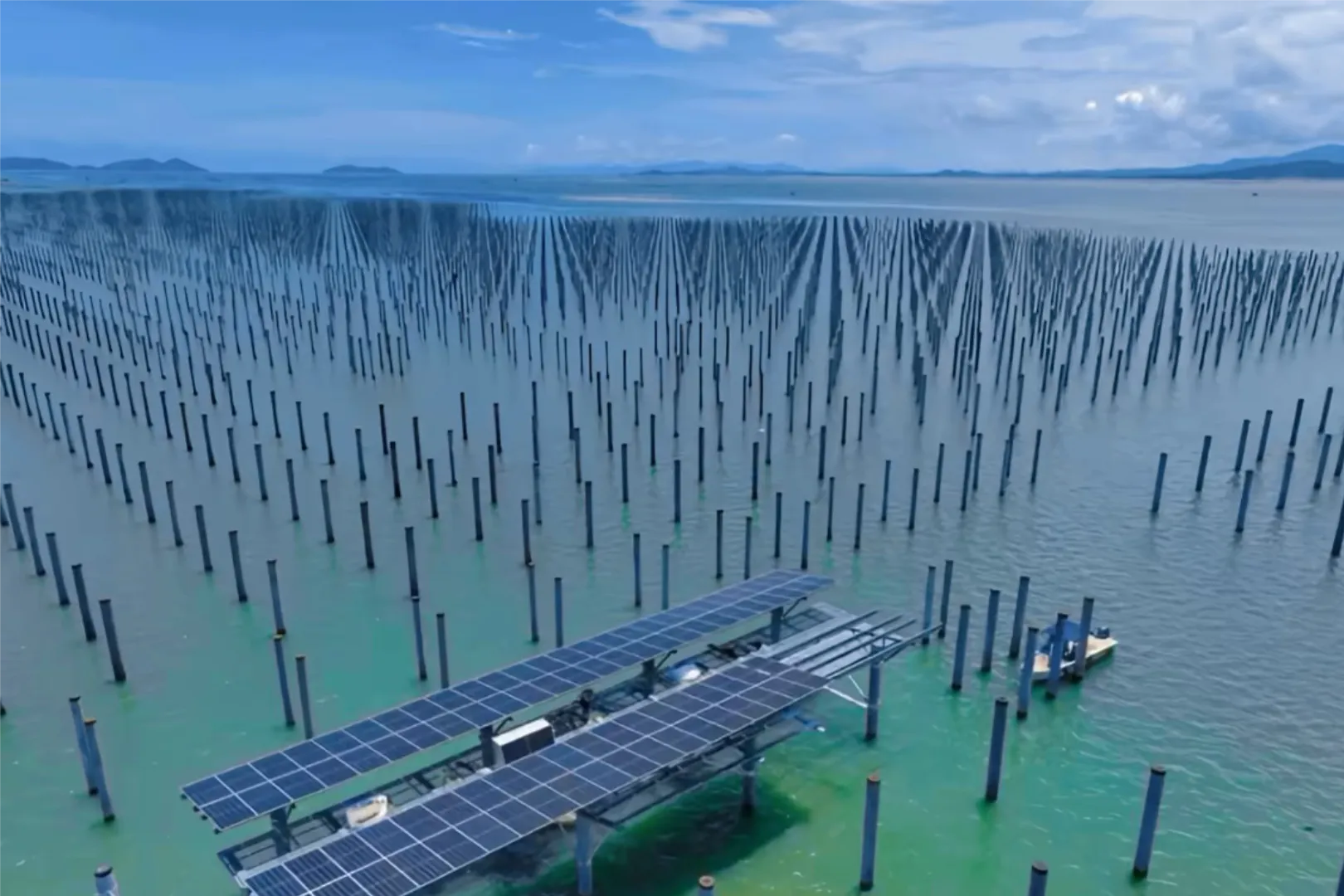

In highly corrosive environments such as coastal areas or saline-alkali soils, the corrosion resistance of PHC piles is particularly critical.

Research indicates that PHC piles can meet code requirements when appropriate corrosion protection measures are implemented, such as ensuring the concrete’s water resistance rating is no less than P10, maintaining a minimum reinforcing steel cover thickness of 30mm, and incorporating composite corrosion-resistant materials.

Additionally, PHC piles exhibit good durability, making them suitable for long-term use.

High Cost-effectiveness

The unit cost of PHC piles is relatively low, approximately 40% cheaper than concrete cast-in-place piles. Under the same load-bearing conditions, PHC piles are significantly more cost-effective than steel pipe piles.

In addition, PHC piles generate less construction pollution and material waste, further reducing project costs. This economic advantage is particularly evident in large-scale photovoltaic projects.

The choice of PHC precast piles for the installation of solar tracking systems is based on their comprehensive advantages in terms of load-bearing capacity, construction efficiency, economy, durability, adaptability, and environmental friendliness. These characteristics make PHC piles an ideal choice for pile foundations in photovoltaic projects, especially for the construction of photovoltaic power stations in complex geological conditions such as coastal areas, soft soil foundations, and saline-alkali land.